So, pulleys-or in some cases, centrifugal clutches-provide a mechanical speed-changing solution.

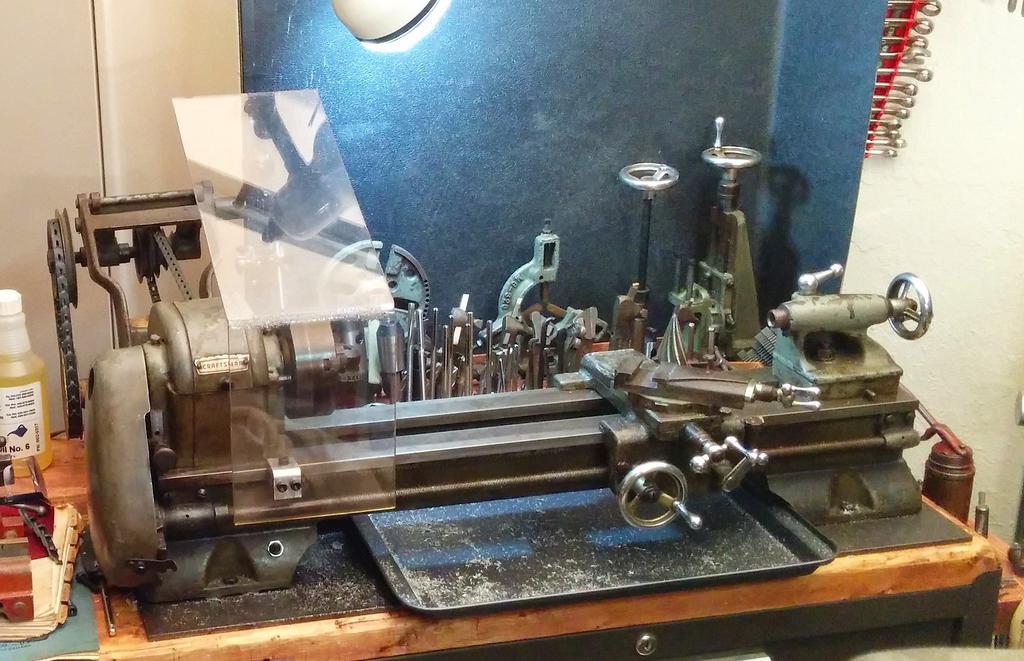

ATLAS LATHE BELT CHANGE FULL

Full torque at variable speeds is what you’ll get for your money.Ĭhris Marshall: There’s a reason why typical drill presses and lathes with induction-style AC motors have stepped pulley systems: you can’t vary their operating speed electrically without potentially overheating the motor and damaging it. If your pockets are deep, and you don’t want to try a jackshaft, then a DC motor is your next best option. It uses the most simple “old-school” technology, but it really works.

Bill was a personal friend of mine, and his “infinitely variable speed foot pedal” is wonderful. If you want to see how an old master ivory and bone turner did it, read Bill Jones’ Notes from the Turning Shop.

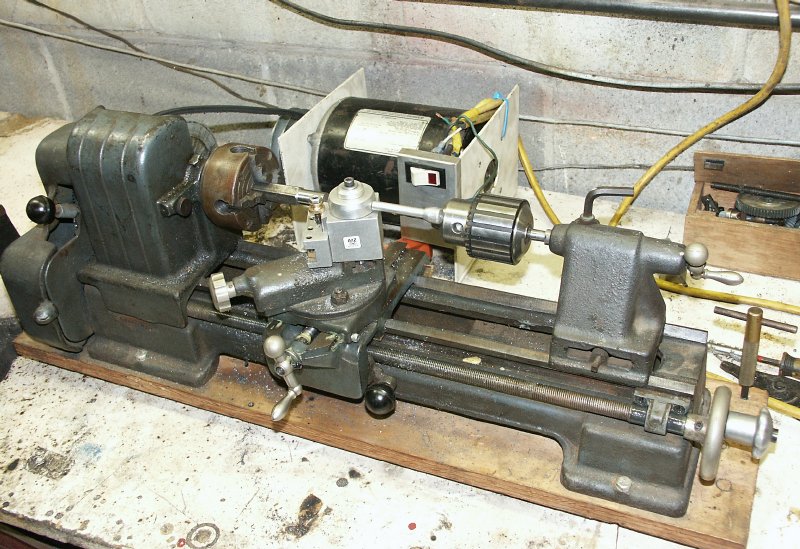

Instead of trying to change out the pulleys, add a jackshaft with its own pulleys in between the lathe head and the motor.

ATLAS LATHE BELT CHANGE HOW TO

How to slow it down? My best answer, and a choice I use myself, is a jack shaft. So with electric motors comes fast spindle speeds. It is more enjoyable work, too.įast motors are cheaper, though. You CAN turn beautifully with slower speeds. They were not turning at thousands of RPM. Remember, all that fine furniture in the museums with exquisite turnings was done with foot treadle type lathes. I like to turn slower – just fast enough to make things work. More speed usually just means more heat and shorter tool edge life. Stump = 2,985 feet per minute surface speed.) The size of the object being turned has a great impact on the cutting speed of the project.įor me, almost everybody turns too fast. (I hate math, but these two examples figure out to be this at 475 RPM: Bobbin = 23 feet per minute surface speed. A tree stump two feet in diameter makes that treadmill go fast. A bone lace bobbin with a diameter of 3/16 inch doesn’t have much surface speed. Surface Feet Per Minute represents the “ground speed” of the wood going past your cutter. That said, I’m in total agreement with you that your lathe is going too fast for bigger work. So, making things round and smooth is fun for me. I do turn bone and exotic hardwoods, along with my clock lathe work, too. Most of my work has been restoring the turnings others have done, and turnings typically found on fine furniture. Turning has always had a special place in my world. Tim Inman: Now you’re into my favorite territory. Is there a way to convert an AC motor to variable speed? – Rusty Aurand I feel this is a little fast for a chunk of burl that large. The slowest speed on the lathe, as far as I can calculate, is 475 rpm. The lathe has a 7-1/2″ throw, and I would like to turn the largest bowl possible. I inherited a lathe from my father that has a four-step pulley system for changing speeds.

0 kommentar(er)

0 kommentar(er)